Coval Metal Coating

Coval Metal Coating

Coval Metal Coating Protection

Coval Metal Coat is a high-performance coating that protects all metal surfaces. Coval Metal Coat creates a matrix of super hard nano sized particles that crosslink with the substrate and with itself to provide a long-lasting barrier and superior resistance to rust, moisture, corrosion, salt-spray, acid rain, UV damage, oxidation, galvanic corrosion, animal and bird-waste damage, wind drag, and dirt and ice build-up. Our pipeline formula, MC-400, is specifically designed to coat the insides of oil, water, and gas pipelines to prevent corrosion and improve flow dynamics. The coating is extremely tough, resistant to acids, Hydrogen Sulfide (H2S) and alkalines

Coval molecular nanotechnology will extend the life of your valuable assets – oil refineries, pipelines, tanks, bridges, trucks, overpasses, transmission towers and the superstructure of ships. Coval Metal Coat will protect iron, steel, stainless steel, aluminium, galvanized steel, copper, bronze, powder-coated, painted, or primed metals. Think of Coval Metal Coat as armour for your raw or painted metal.

Coval Group has created the next generation of nano coating technology.

Our coatings create a matrix with nano sized particles that

crosslink with the substrate and with itself. This high-tension

crosslinking creates an entirely new surface that is totally waterproof,

extremely resistant to abrasion, acids, stains, mold and corrosion. They

are UV stable and will prevent paint from fading.

These coatings are single component and easy to apply. They contain

less than 100g/l VOC and contain no known carcinogens under

Proposition 656 of the California Drinking Water and Toxic Enforcement

Act of 1986.

Metal Primer 207 (MP-207)

MP-207 is a surface preparation product guaranteed to improve coating

adhesion and mitigate under-film corrosion.

Achieve the ultimate visual and microscopically clean metal in minutes, stop flash rust and prevent corrosion under coatings well into the future. Apply MP-20 to metal assets or components to remove impurities in one step.

CleanWirx 207 will double the time between significant coating failure maintenance events and works with any coating system to create a uniform receptive surface for improved adhesion and consistent, optimized coating performance.

SCAQMD : Coval Metal Coat contains less than 100 g/L VOC. Coval Metal Coat exceeds CAQMD Rule 1113 requirements, known as the highest in air quality control standards in the country.

PROP 65: Coval Metal Coat contains no known carcinogens under Proposition 65, California’s Drinking Water and Toxic Enforcement Act of 1986.

TEST

- ASTM D-3359-09 Adhesion Standard test

- ASTM D-3363 Film Hardness Taper

- ASTM D-2047 Static Coefficient

- ASTM D-2047 Static Coefficient

- (ISO 4623) Corrosion and Filiform

RESULTS

- 300 hours 4B

- 39.11 average

- Passes ADA requirements

- No filiform or corrosion

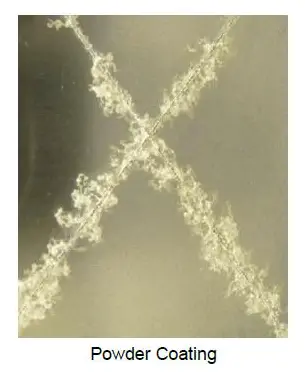

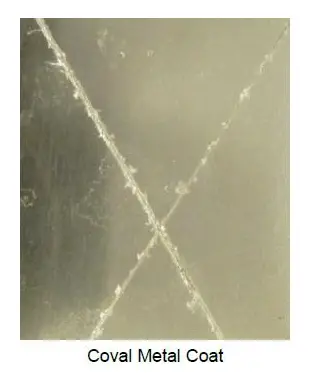

Samples were scribed with an ‘X’ exposed to NSS for 23 hours then placed in humidity cabinets set at 40 deg C and 80% humidity for 1,000 hours (six weeks)

E96-10 Water Vapor Transmission

Average WVT 0.3473 gr/ft2/hr, average perms 0.8376 gr/ft2/hr

G155 Xenon Arc, wavelength 340nm irradiance 1.0 w/m2

500 hours, slight change

ISO 4623 International Standard Corrosion

No Corrosion

ISO 4628-10 International Standard, Degradation of Coating

No Degradation of coating

Month Electrolysis and Corrosion Test

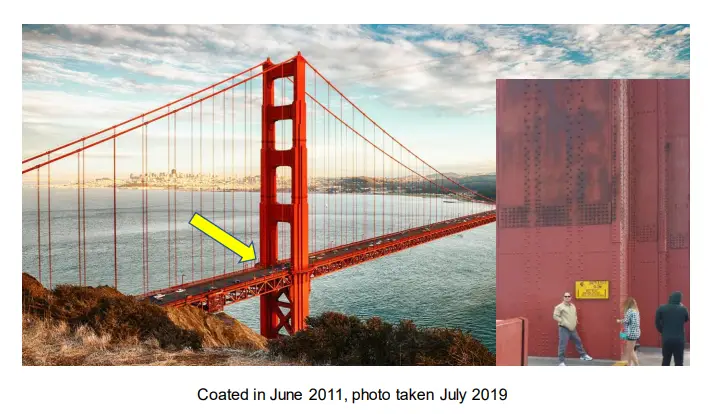

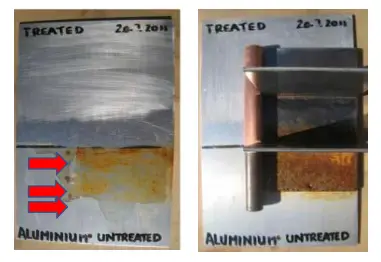

Rectangular piece of standard aluminum, stainless steel and copper were half coated with Metal Coat

The aluminum was placed on a sheet of MDF then the mild steel assembly was placed on to the aluminum. It was placed so that the treated half of the mild steel was on top of the treated half of the aluminum. The copper pipe was placed in the same manner as the mild steel.

The assembly was then placed outside for 1 month – August in San Francisco.

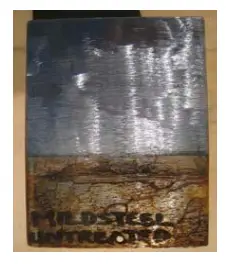

Coval Metal Coating Corrosion Test

Results after 1 month:

The rust is truly setting in. Where the copper tube is sitting, the aluminum is being eaten away in 3 spots in particular due to electrolysis.

Mild steel after 1 month, the rust and electrolysis is much heavier and the coated side is showing no effect.

Treated side after 1 month is showing no corrosion or electrolysis.

Untreated side after 1 month. The “eating away” of the aluminum can be seen where the copper pipe was in contact with it.

Coval Metal Coating Flame Test

3 Minute Coating Combustibility Flame Test

Unpainted mild steel coated with Coval Metal Coat was heated with an 1,800-degree F propane torch for 3 minutes.

The metal darkened beneath, the Metal Coat coating did not ignite, blister or peel. No upper heat range has been established.

Alcoa Aluminum Manufacturing Plant.

Alcoa Aluminum is coating their aluminum tuck rims with Coval Metal Coat. One rim was cut into pie shape samples to review the coating performance.

The coating did not chip, peel or flake after being cut with

both band saw and C&C machine.