Coval Concrete

Coval Industrial Floor Coatings

Coval Concrete Floor Coatings

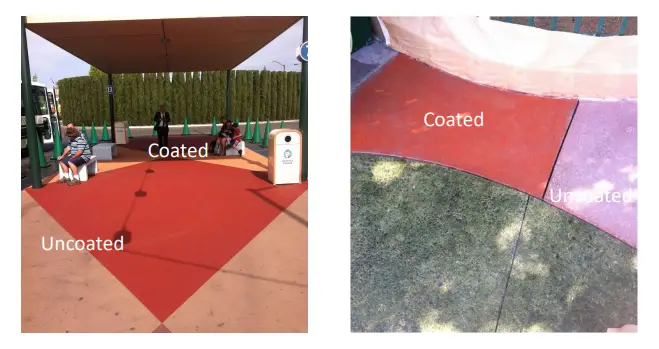

If you want to dramatically extend the life of your concrete floors, Coval Concrete Coat is a highly durable, UV stable, peel and flake-resistant single component protective coating that extends the life of concrete surfaces. Concrete coat bonds with the surface and creates a superior barrier against moisture, oil, mild acids, stains, abrasion, and graffiti.

Concrete coat is very cost effective, super long lasting and low maintenance compared to other types of concrete coatings on the market. It can be used on all types of concrete including:

- Floors

- Masonry

- Poured concrete

- Concrete countertops

- Brick

- Precast concrete walls

- Cement blocks

- Tunnel Waterproofing

- Dams

- Concrete tanks

Concrete Coat gives you a vast variety of finished looks, too. The finishes are available in gloss, satin and matte. It can be brushed, sprayed, or rolled onto the surface, and it has a super quick drying time! The best part is that it only requires one coat!

Concrete coat can give you a finish that is similar but superior to concrete floor polishing, concrete floor sealing, or concrete floor staining. In fact, Concrete Coat can also be used as a final protective layer over our Quick Seal and Enhance for an incredibly fast process for a beautifully stained concrete floor system.

Don’t let your concrete get ruined by water damage, stains and wear and tear. Use Coval Concrete Coat and keep your floors in great condition for years to come!

Coval Group has created the next generation of nano coating technology.

Our coatings create a matrix with nano sized particles that crosslink with the substrate and with itself. This high-tension crosslinking creates an entirely new surface that is totally waterproof, extremely resistant to abrasion, acids, stains, mold and corrosion. They are UV stable and will prevent paint from fading.

These coatings are single component and extremely easy to apply.

They contain less than 100g/l VOC and contain no known carcinogens under Proposition 656 of the California Drinking Water and Toxic Enforcement Act of 1986.

Concrete Coat

ASTM C1353-09: Coval Concrete Coat scored an average of 39.11 on the Taber Abraser Test. Coval Concrete Coat scored higher than granite in resistance wear.

ASTM C1353-09: Coval Concrete Coat scored a 10, the highest rating. It indicates no rust or corrosion after 7 days of Cyclic Salt Fog/UV Exposure and an additional 7 days in a QUV Accelerated Weathering Tester.

SCAQMD: Coval Concrete Coat contains less than 100 g/L VOC. Coval Concrete Coat exceeds CAQMD Rule 1113 requirements, known as the highest in air quality control standards in the country.

PROP 65: Coval Concrete Coat contains no known carcinogens under Proposition 65,

California’s Drinking Water and Toxic Enforcement Act of 1986

Dyess Airforce Base – Texas

Concrete Coat

- Asset preservation

- Reduce cleaning time

- No longer need harsh chemicals

- Low VOC’s

- UV Resistant

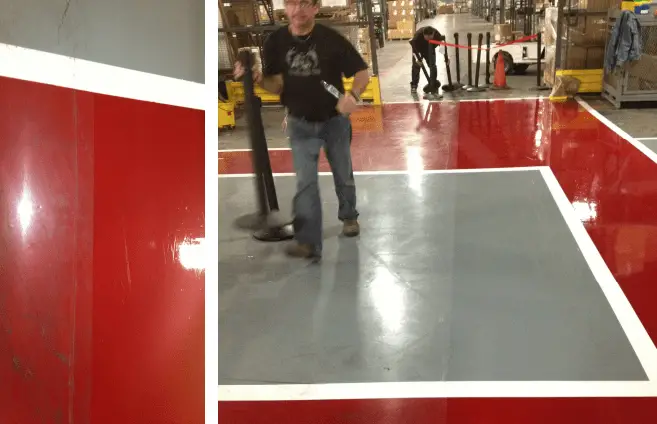

Hangar floors need to be able to handle, extreme conditions including hot tires, fuel spills, and hydraulic fluid spills containing Skydrol!

- Thin film coating

- Single component

- Extremely hard waterproof coating

- Superior protection from moisture, corrosion, salt spray

- Protects against salt spray, acid rain, UV damage, galvanic corrosion, dirt, and ice.

- Extremely easy to apply and will not peel, crack, or bubble

Concrete corrosion is caused by chlorides dissolved in water permeate through the concrete and reach the seal rebar.

Concrete Coat is applied after the concrete has cured and creates a waterproof barrier with is almost invisible.

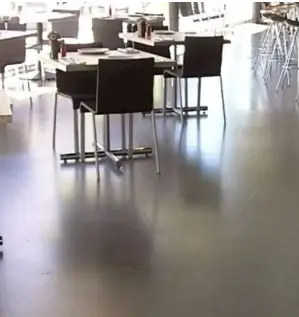

Concrete Coat

- Creates a completely waterproof barrier

- Protect against concrete corrosion

- 5,000 sq. feet Polished concrete

- Quarterly Strip and Wax – no longer required

- Cleaning time reduced by 65%

- Stain free after 8 years

- ROI less than 3 months

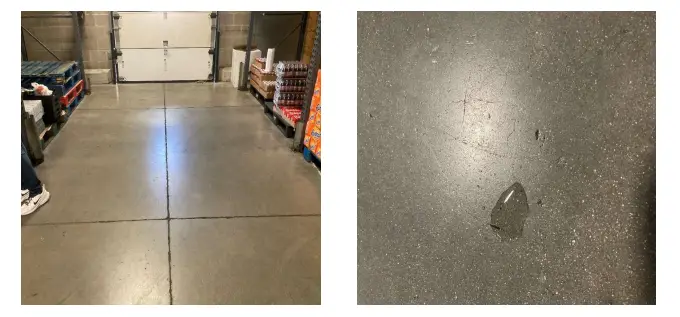

Loading docs require a coating that can take the tough punishment of constant forklifts and food spills. 7 years after Coval Concrete Coat was applied, the floor is still clean and waterproof!

HEB Loading Dock – 7 years later

“7 years after installation they are still going a great job. They are easy to clean with an auto-scrubber and neutral cleaner. This saves us time and money” – HEB Maintenance Manager

- Prevent painted surfaces fading

- Stain resistant

- Easy to clean

- Looks great

- AntiGraffiti

Taken 4 years after Concrete Coat was applied